Advanced Graphene Coating Technology

Sublimation Inc. partners with IGL Coatings to provide cutting-edge graphene nanotube technology. Our Aegis and Eclipse coating systems deliver unmatched protection when applied to freshly dry ice cleaned surfaces.

Advanced Materials Science

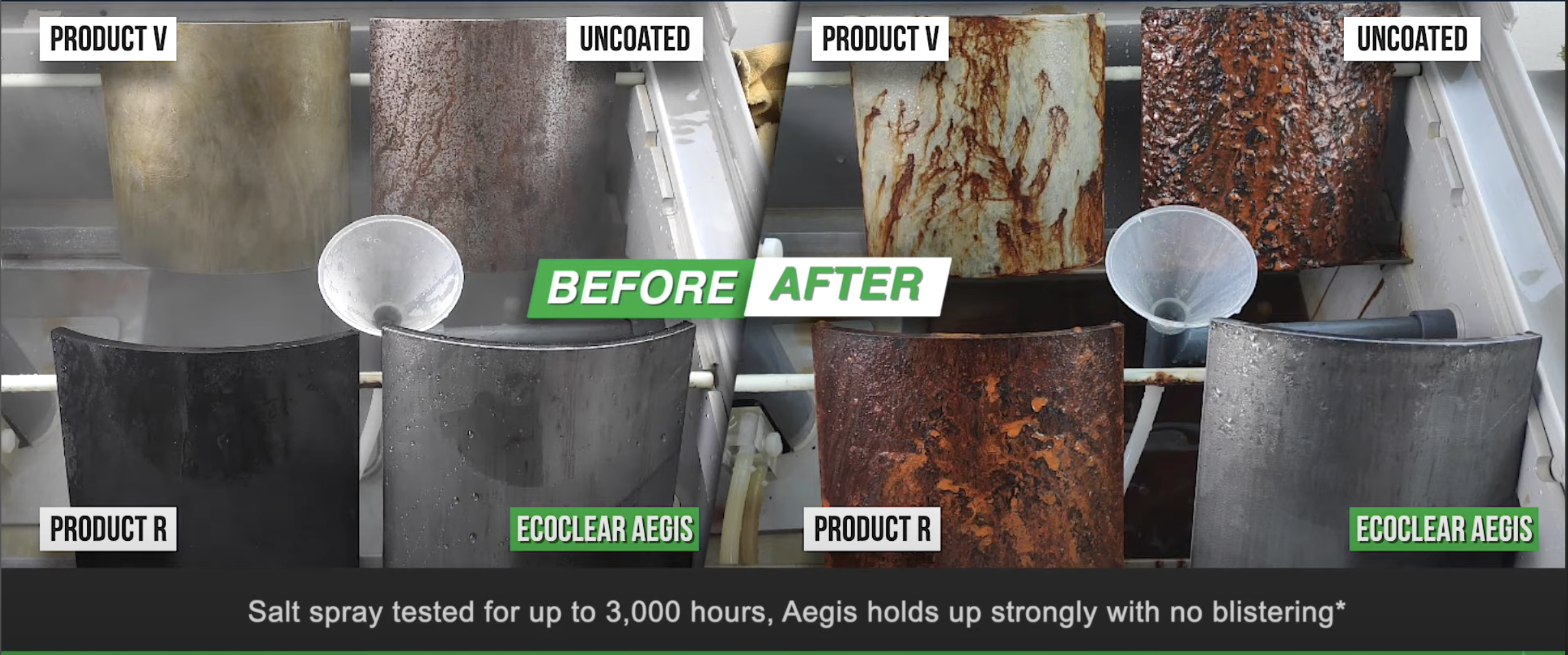

Anti-Corrosion Protection

Salt spray tested for up to 3,000 hours, Aegis holds up strongly with no blistering*

Real-world testing demonstrates the exceptional anti-corrosion properties of our graphene-enhanced coatings. After 3,000 hours of salt spray exposure, surfaces protected with EcoClear Aegis show virtually no corrosion compared to uncoated materials that exhibit severe rust and degradation.

Why Graphene Coatings After Dry Ice Cleaning

Perfect Surface Preparation

Dry ice cleaning creates the ideal surface for graphene coating application. The process removes all contaminants, oils, and residues without leaving any chemical traces, ensuring maximum coating adhesion and performance.

- • Completely clean surface at molecular level

- • No chemical residues to interfere with coating bonding

- • Optimal surface energy for coating application

- • Extended coating lifespan through proper preparation

Long-Term Protection Benefits

Applying graphene coatings to freshly cleaned surfaces ensures that your investment in cleaning lasts significantly longer. The hydrophobic and anti-corrosion properties keep surfaces cleaner for extended periods.

- • 3-5x longer intervals between deep cleanings

- • Self-cleaning properties reduce maintenance

- • Protection against environmental contaminants

- • Cost savings through reduced cleaning frequency

IGL Aegis - Graphene Nanotube Protection

IGL Aegis

Anti-Corrosion Clear Coating

Aegis is an advanced anti-corrosion clear coating reinforced with graphene nanotubes to enhance performance and mechanical properties. The Graphene Nanotubes Technology (GNT) acts as a barrier against oxidation and chemical attacks.

Key Technologies:

- Graphene Nanotubes Technology (GNT) for superior barrier properties

- Enhanced mechanical properties and durability

- Protection against oxidation and chemical attacks

Applications & Benefits:

Automotive & Marine

Ideal for undercarriages, engine bays, and marine applications where corrosion resistance is critical. Provides long-term protection against salt, chemicals, and environmental damage.

Industrial Equipment

Perfect for heavy machinery, construction equipment, and industrial surfaces exposed to harsh chemicals and environmental conditions.

Aerospace Applications

Provides critical protection for aircraft components against corrosion while maintaining lightweight properties essential for aviation applications.

Ecocoat Eclipse - Hydrophobic Ceramic Protection

Ecocoat Eclipse

Advanced Ceramic Coating

Eclipse is a high-performance ceramic coating that offers exceptional hydrophobic properties, repelling water and contaminants while providing a durable protective barrier. Often used in conjunction with Aegis for comprehensive protection systems.

Key Features:

- Superior hydrophobic properties for water and contaminant repulsion

- Self-cleaning surface reduces maintenance requirements

- Enhanced gloss and aesthetic appearance

Performance Benefits:

Water Repulsion

Advanced hydrophobic technology causes water to bead and roll off surfaces, carrying away dirt and contaminants for natural self-cleaning action.

Contaminant Resistance

Creates a barrier against environmental pollutants, bird droppings, tree sap, and other contaminants that can damage or stain surfaces.

UV Protection

Provides protection against harmful UV rays that can cause fading, oxidation, and degradation of underlying surfaces.

Aegis + Eclipse: Complete Protection System

When combined, Aegis and Eclipse create a comprehensive protection system that addresses both corrosion resistance and surface maintenance, maximizing the benefits of your dry ice cleaning investment.

Professional Application Process

Dry Ice Cleaning

Complete surface preparation using our chemical-free dry ice cleaning technology

Surface Inspection

Thorough inspection to ensure optimal surface conditions for coating application

Coating Application

Professional application of Aegis and/or Eclipse coatings using certified techniques

Curing & Quality Check

Proper curing process and final quality inspection to ensure optimal performance

Advanced Materials Science

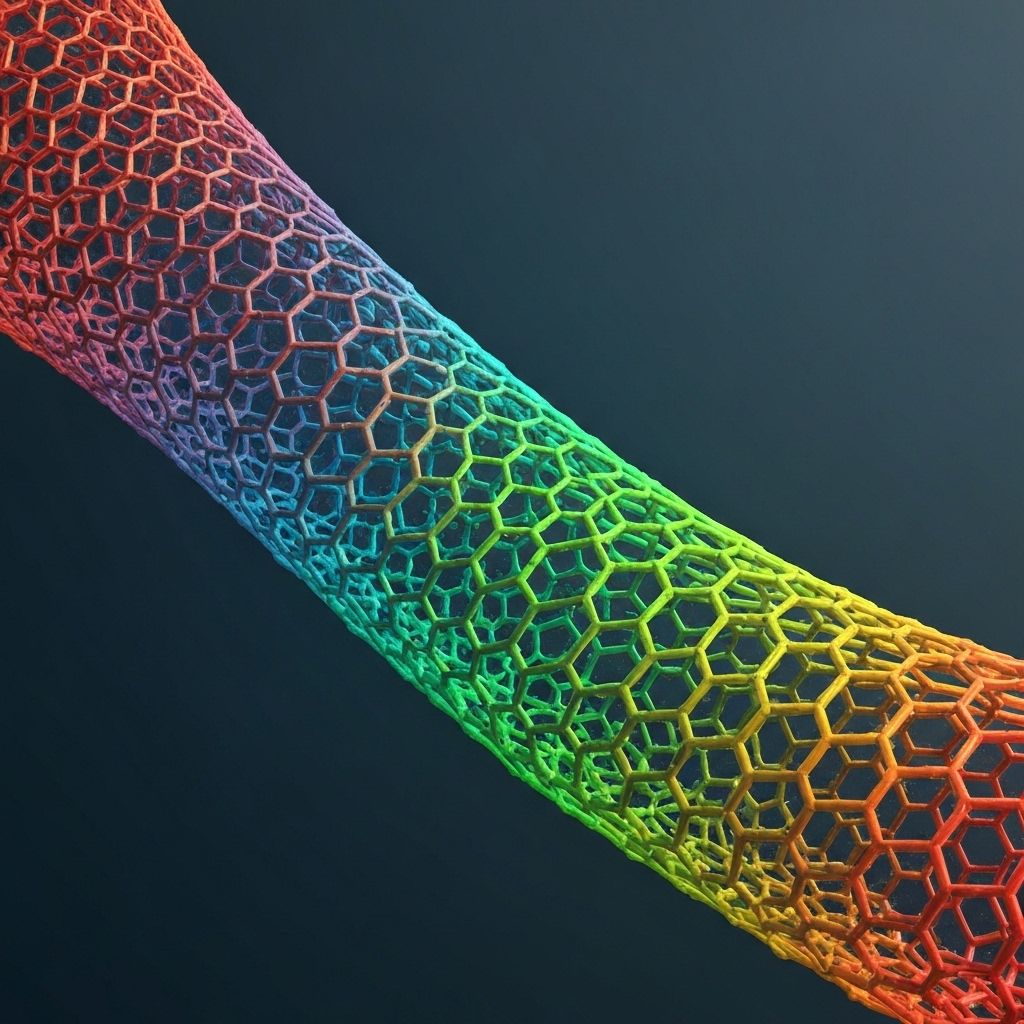

Graphene Nanotube Technology

Graphene nanotube molecular structure - 200x stronger than steel

Graphene nanotubes represent one of the strongest materials known to science, with exceptional mechanical properties and barrier characteristics. When integrated into coating systems, they provide unmatched protection and durability.

- • 200x stronger than steel by weight

- • Superior electrical and thermal conductivity

- • Exceptional chemical resistance

- • Molecular-level barrier properties

Hydrophobic Properties

Hydrophobic coating creates perfect water beading and self-cleaning action

Advanced ceramic coating technology creates a semi-permanent bond with surfaces, providing long-lasting protection that outperforms traditional waxes and sealants by orders of magnitude.

- • Covalent bonding for permanent adhesion

- • Hydrophobic contact angles >110°

- • UV stability and color retention

- • Self-healing properties in premium formulations

Ready for Advanced Protection?

Contact Sublimation Inc. today to learn more about our graphene coating services. We'll help you choose the right protection system for your specific needs and applications.